You have to be quick on your feet to make sparkling wine. Harvest starts earlier than for still wines and the time frame is considerably more condensed because there just isn’t as much time to pick the grapes. Harvesting is done during the cool nights to eliminate the need to chill the juices and reduce energy consumption.

Pauline Lhote, the Director of Winemaking at Domaine Chandon in Napa, describes the pace. “We process fruit every single day. When a block is ready, we have only a couple of days to pick it. If today were a harvest day, we would be pressing, and tonight, we would start doing flotation to clarify the juices. By later tonight or tomorrow morning, the wine would already be inoculated.”

Chandon is, of course, all about sparkling — 98% of its wines have bubbles. Its winemaking and production team of nearly 45 employees turns around 30 sparkling wines in this fast-paced environment, from the large case production for its brut and rosé blends to direct-to-consumer lots as small as 200 cases.

To help keep pace and help her better manage the winemaking process, Lhote turned to technology.

Searching for an End-to-End Solution for Sparkling Production

Soon after becoming the Director of Winemaking, Chandon’s IT team told Lhote, “You might want to start changing.” They explained that her current wine management software was not cloud-based and risked the loss of all the data about operations if something happened to the supplier’s server. She needed something more secure.

As the search for a solution began, she realized there were other problems a new system could address. Their operations relied on multiple software systems that were disconnected, so Lhote’s team relied on time-consuming manual, paper-based workflows prone to errors. It was also challenging to track and calculate production costs for each wine and make informed financial decisions.

As the search went on, Lhote began to visualize a solution that was customized for sparkling wine production, from base wine to dosage through tirage, aging and packaging. “No system tracked the liqueur added at disgorging. We wanted to have full traceability of what is going into the bottle.”

Finding a collaborative technology partner

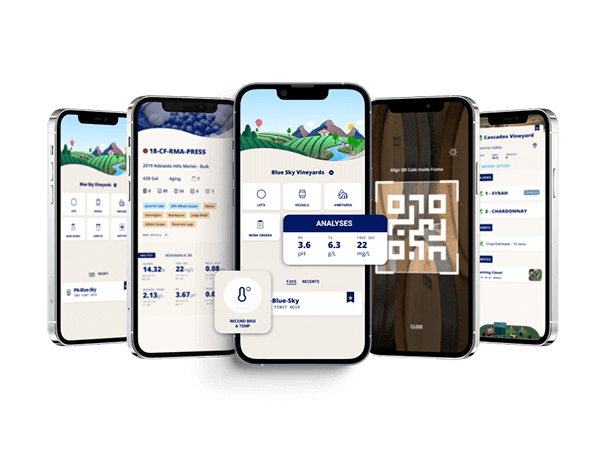

The search brought her to InnoVint, which was willing to collaborate on bringing her vision to life.

Ashley Leonard, InnoVint’s CEO, explains why. “We’re helping wineries run more efficient businesses, production operations and financial cost accounting. For Chandon, this meant empowering Pauline and her team to manage their workflows, including méthode champenoise, from grape to finished product.”

Lhote chose InnoVint for a number of reasons beyond its willingness to collaborate:

Real-Time Data, Anytime, Anywhere: Real-time updates throughout the winemaking process give all departments instant access to live data and seamless communications.

Paperless Workflow: A digital system replaces manual, paper-based processes and duplicate data entry with automated work orders, tasks and inventory updates.

Single Source of Truth: Consolidating production data into a centralized InnoVint platform for tracking and reporting delivers data entry consistency, reliable, real-time reporting and enhanced decision-making.

Still, Lhote was apprehensive about moving to a fully digital system. “The winemaking team wanted to make the move, but I worried that our cellar team, some of whom had been with us for 20-plus years, would struggle to adapt.”

“A lot of the hesitation that wineries have about investing in technology is the fear of change,” says Leonard. “Pauline runs a tight ship with no room for error. The solution had to plug in effectively and efficiently to the lean team she runs.”

It turned out that the cellar team was as on board as the winemakers because InnoVint’s user-friendly design was easy for everyone to use and fit seamlessly into their existing workflows, so winemakers, seasonal staff and new hires could all navigate the system with minimal training, reducing onboarding from days to an hour.

“Finding InnoVint was like stepping into the modern world,” says Lhote. “It has been a huge change that allows us to move things at the cadence that we need to make high-quality sparkling wines. The software is intuitive, and we can actually see in real time when they are pressing the grapes or creating a work order. From a winemaker’s point of view, it was life-changing.“

The digital transformation also delivered a financial boon. Eliminating the need for manual and duplicate data entry, which was previously a full-time role, saved Chandon over $75,000 annually. Using InnoVint also allowed their finance team to connect it to their existing Power BI platform, helping them make more informed decisions on pricing, cost management, and production efficiency.

Learn more about Chandon’s digital transformation and reach out to InnoVint to learn more about their winery operating system.